PAGANI EUGENIO srl is ISO9001:2015 certified with certificate Nr. 50 100 11507.

Over the years, this certification has helped us keep our primary and fundamental objective in focus: total customer satisfaction, an indispensable precondition for success over time.

PAGANI EUGENIO Quality

In particular, we subject the following phases to protocol verification according to strict consolidated ratings:

- Timeliness of deliveries;

- Delivery flexibility;

- Reliability;

- Good quality/price ratio;

- Percentage of production waste in relation to the total volume.

Our objectives for concrete and constant improvement are systematically defined, planned and verified annually for each company area during a quality system review.

Specific inspections

As regards product-specific inspections, in addition to standard inspections, in case of need and in agreement with the customer, more in-depth checks can be carried out, such as:

- Test with penetrating liquids;

- Magnetoscopic test;

- Ultrasound test;

- Corrosion resistance in neutral salt spray;

- Facing adhesion test;

- Hardness and micro hardness of facings;

- Check of geometries on three-dimensional measuring equipment.

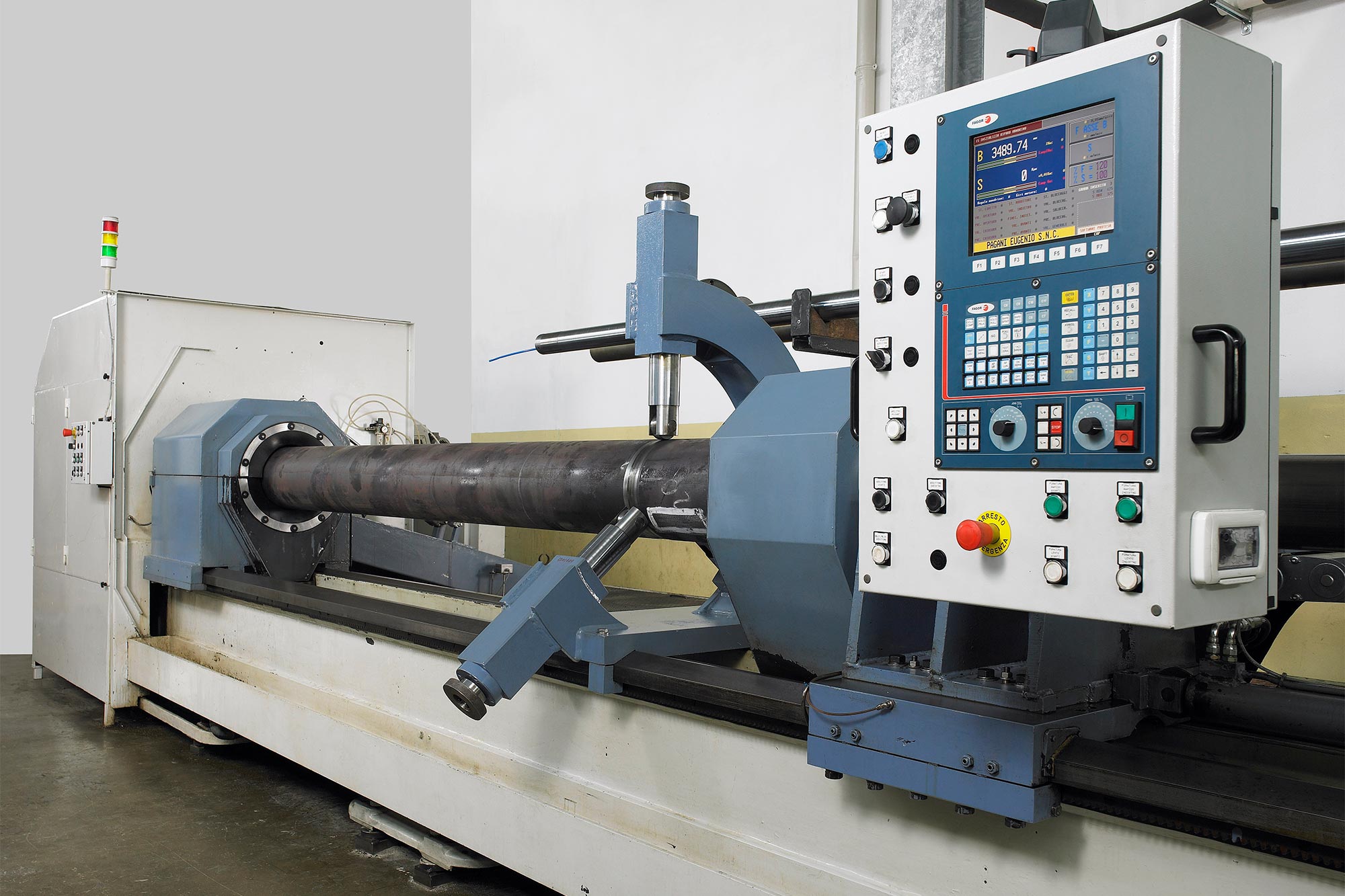

Our machines

In detail, our CNC machines are:

UTITA T450 lathe

Comev Leonardo lathe

Labor lathe

Tacchi HD3 lathe

Doosan PUMA 3100 lathe

GIANA rolling machine

VDF boring machine

L1 Vertical honing machine

L2 Vertical honing machine

L3 Horizontal honing machine

AF cylinder assembly, disassembly and testing bench

Our production department uses high-tech CAD-CAM tools for programming the machines and we can complete our lathe-turned products with holes, tapping and milling according to drawing.

As for testing, our department is equipped with traditional instruments certified according to UNI EN ISO 9001:2015 and the obtained measurements can be recorded for all the pieces in a batch or on a sample basis.

Our company also relies on external experts for the verification of geometry data (concentricity, perpendicularity, flatness) on three-dimensional equipment.