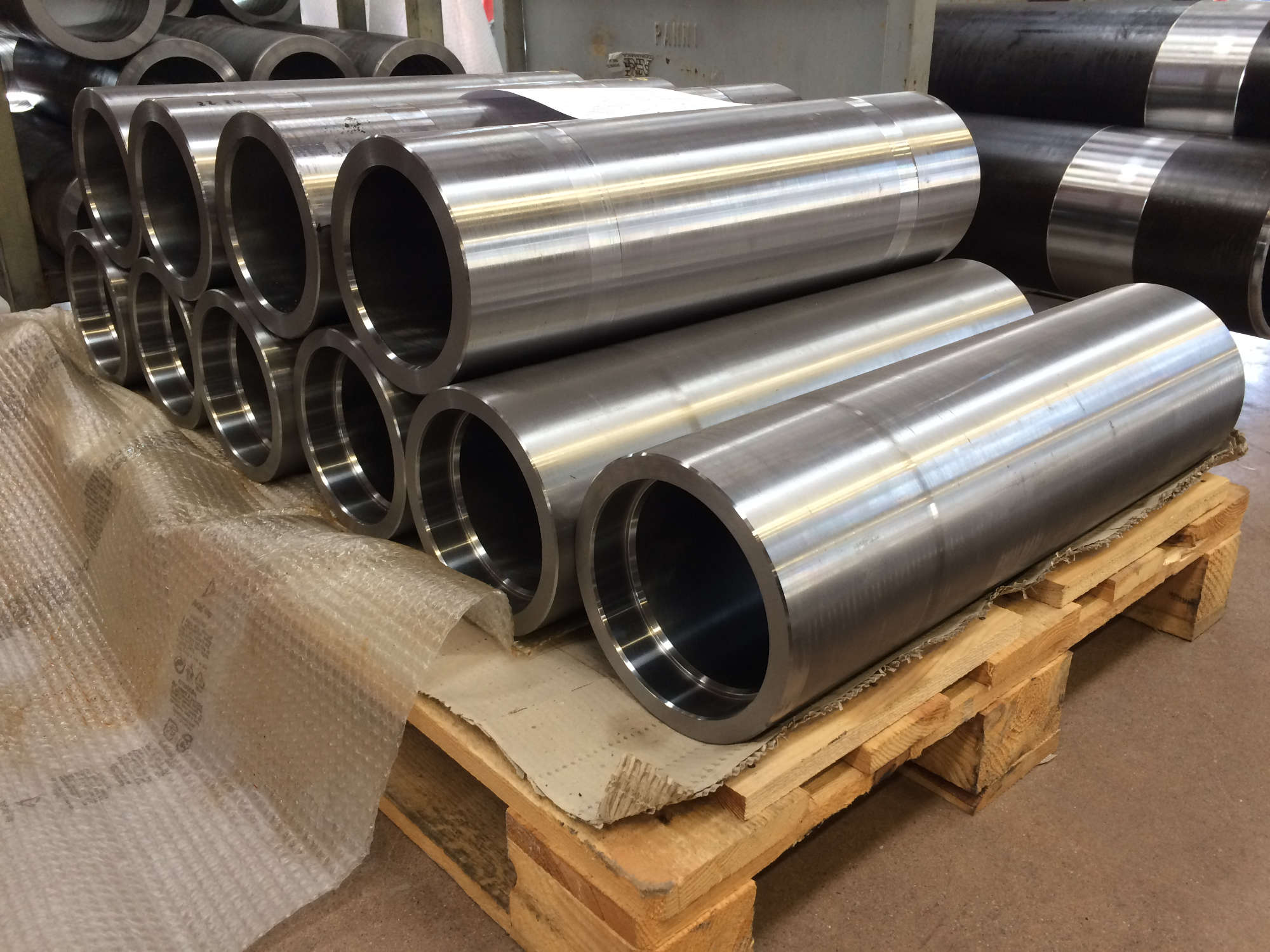

Turning is one of the most commonly required machining processes for pipes and liners for hydrodynamic cylinders. Through this operation, which is carried out by rotating the component concerned, the removal of any excess material is obtained, by strictly following the instructions found in specific technical drawings.

Processing phases

In particular, the production of components such as liners for hydraulic cylinders requires a production cycle that includes a sequence of phases to be strictly observed, in order to guarantee machining quality.

For example, welding, when required by the circumstances, must necessarily be carried out before honing, to avoid any deformation, while turning is performed before welding to prepare the workpieces and then finish them.

Additionally, when geometric tolerances ensuring tight concentricity and perpendicularity with respect to the honed hole are required, then it is necessary to design a production cycle including reworking through final turning.

PAGANI EUGENIO srl is equipped with turning centres that allow roughing and finishing operations to be carried out – as well as milling, drilling and tapping according to drawings for product finishing.

In an optimized layout, these processes are integrated with boring, honing and rolling, with the aim of reducing production times as much as possible.

Growing Programme

We have recently commissioned an important piece of machinery, within the scope of our planned growth and investment program. Specifically, this machine will be used to complete customised products, in particular liners and stems for hydraulic cylinders.

This is the TACCHI HD3 CNC 600 x 11000 lathe which can perform turning, drilling and milling operations on workpieces of considerable size, up to at least 11 metres in length and related diameters.

This innovation allows us to significantly expand our range of products and services, with a view to achieving the highest possible level of customer satisfaction.

Please feel free to contact us to learn about the extra value that this machine can bring to your customized projects – including boring and honing machining.

Case history

July 21, 2022

Survey and manufacturing of a random check chrome-plated rod

A relevant Italian company with branches in various eastern European countries, asked our intervention to revamp into optimal efficiency conditions a cylinder placed into an application for the waste management

June 21, 2022

Perfectly aligned honing

On behalf of one of our historical and most important client, we planned the definition of a production cycle combined with turning and honing which ensured the required geometries with reliable repeatability over the whole producon