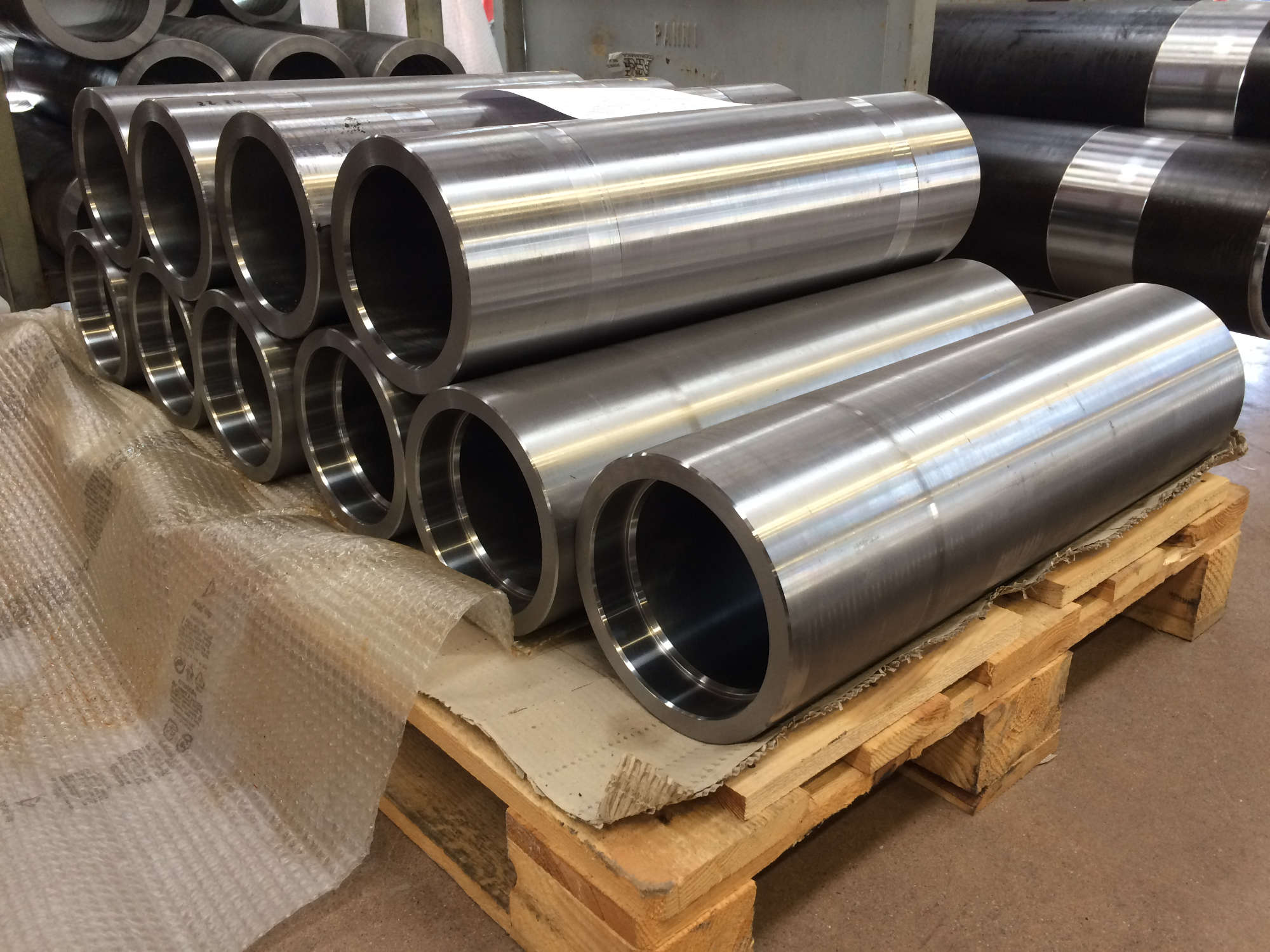

Last year, one of our historical and most important client, proposed us a partnership oriented to the imrovement of product quality Such project substantiated also through the purchasing of a three-dimensional measuring machine DEA Obviously besides the esteem and the consolidated relation the client’s choice fell on us also in light of our remarkable gained experience during the years, in the production of barrels for the gas compressors.

The first detections on the geometries pointed out the not perfect perpendicularity and concentricily of the processes, clearly occured during the internal honing.

From a first analysis it seemed to us impracticable to maintain a geometical tolerance between 0,01-0,02 millimeters, without resorting to an internal and esternal grinding but, from the client’s point of view such claim from the technical department was mandatory, so that we and to adopt an alternative solution.

This answer has matured by the active collaboration between our production department and the client’s quality manager From such honest and synergistic encounter between the parts, we could define a production cycle with turning and honing that can garantee the required geometries with reliable repeteabliity over the whole production.

Once more the dedication, flexibility and orientation to the obstacle overcoming, combined with the expertise, have helped us to get to the bottom of very complicated issue. we are obviously very glad to have fully satisfied or client and partner.