We can confidently state that we are ideal partners for all industry players. Our focus on customer satisfaction with no room for compromise, our broad and many-sided expertise combined with long-standing experience, which allow us to effectively respond to even the most complex needs, are just some of the reasons for choosing us. Put us to the test to find out many more!

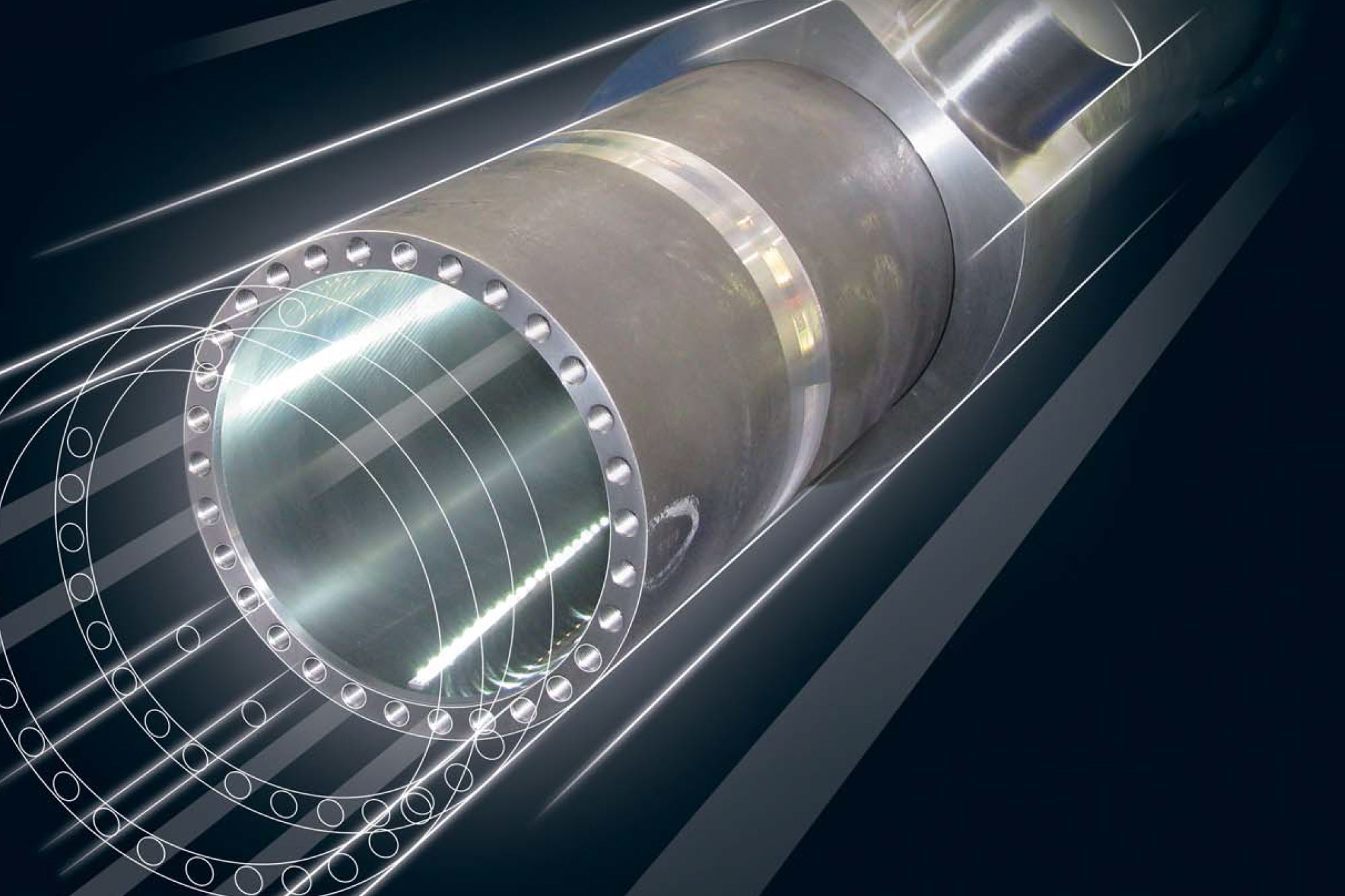

Customised machining

Our quality processes are highly customised: in absolute terms, the tailor-made products that we manufacture account for 98% of our total output. Technical drawings are often provided by customers but we can also supply turnkey solutions by creating the required drawings based on the indications received and building a hydraulic cylinder from start to finish.

We offer a wide range of applications while assisting and following customers through each process stage, starting from the very first inquiry, and responding at best to their technical and application expectations, however complex.

Our cylinders are used in the most diverse and challenging environments, at extreme temperatures, in water, in the presence of sand and sediments, while always remaining flawless and high performing.

High degree of customer satisfaction and quality protocols

Our measured degree of customer satisfaction is very high and out of 15340 pieces/year (2020 survey), there are very few reported non-conformities for which, however, we invariably proposed an effective solution, for a total of zero unresolved non-conformities.

We have a quality control protocol and annual performance improvement goals that we constantly strive to achieve. Among other binding parameters, with a view to always offering the best possible customer experience, we process every inquiry within a maximum response time of 7 days.

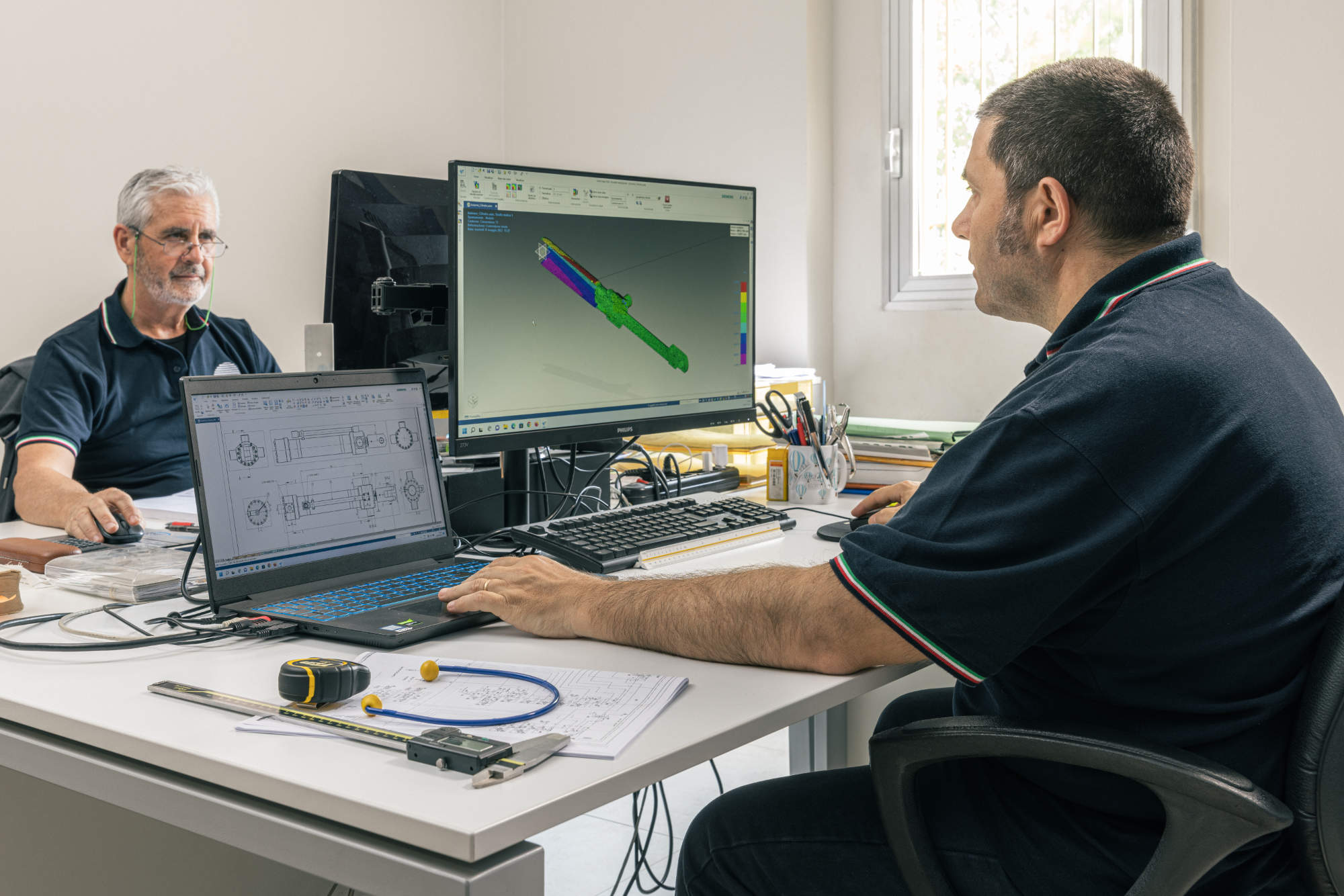

The value of human resources

Our workers are the real assets of our company: without their daily dedication and professionalism, our process automation, technology or industrial intelligence would be far from sufficient. Many have been with us for decades: technicians and skilled workers who have been on an outstanding personal growth path and are enormously proud of their achievements.

It is part of our mission to continue to raise the level of overall corporate expertise, on the one hand by hiring, when required, human resources capable of adding know-how and value to our product and service range, and on the other hand by constantly investing in highly qualifying training. In this way, both top quality, down to the smallest detail of the production process, and consulting support offered to customers are guaranteed.

To achieve this goal, the company also relies on highly specialised expert partners with an outstanding professional profile, who are well integrated and who carry out their assigned tasks with enthusiastic commitment and participation.

We believe work ethics to be a pillar of our company strategy, which goes hand in hand with the empowerment of people and fair, solid human relationships within the company.

The production process

Every single phase from preliminary planning, through designing to actual processing all the way to assembly, finishing and testing and inspection is closely monitored and managed according to strict parameters of precision and compliance. The organisation of production relies on information technologies with MES 4.0 level automation.

Starting with numerical control lathes, through automatic machinery used for various surface finishes and ending with smart welding equipment, every single system and every single piece of equipment operates under strict control by a highly efficient supervision system.

Innovation and tradition

We intend to keep our focus on the fascinating proposals that R&D and innovation offer to industry 4.0, and we strive to periodically add to our lines new high-tech and high-automation machinery ideally suited to our rigorous standards.

Our vision of the smart industry concept is also expressed through digitization projects that concern both our global company organisation and the specific optimisation of our production chain and its coordination with our design department. Other actions in this field also include programming of data transmission to machine tools, but digitization also powerfully impacts the commercial sphere for better management of information, with virtuous, high-impact effects on the entire customer care organisation.

We have been active in international markets for some time now, deriving from this field of activity new ideas and motivation for our work. One of the projects currently under way concerns a product for the closed-circuit hydraulic actuators market which will make it possible to respond to the need for energy and environmental sustainability, as we, like the entire global community, are particularly sensitive to these issues.

It is a well-tested, methodical but at the same time dynamic system, which allows us to meticulously monitor each processing stage, as well as logistical and management aspects; this level of accuracy and strict compliance with procedures results in near-perfect end products.

At the same time, we are firmly rooted in our “craftsmanship” tradition which makes us highly flexible and easily approachable, without filters, with a view to building highly valuable technical and personal relationships.