A hydraulic cylinder is required when linear motion has to be controlled or a constant force has to be applied. Hydraulic cylinders are among the most important drive generators used in a wide range of machinery in several industrial and non-industrial processes.

Hydraulic cylinders

With a hydraulic cylinder, high speeds can be reached, then very slow speeds and huge forces can be applied with a limited number of components in limited space; in short, it is possible to transfer a highly concentrated amount of power while ensuring maximum suitability for and consistency in the expected performance.

Hydraulic cylinders consist of a limited number of components, i.e. liner, stem, piston – which is at the receiving end of the fluid thrust – and the head which has the purpose of holding all the assembled elements together.

Despite its apparently simple operation, a hydraulic cylinder can feature many constructive differences linked to the use for which it is intended.

Hydraulic cylinders are widely used in many fields, from agricultural machinery to lifters, and from mobile cranes to various industrial applications.

Types of cylinders

Double acting hydraulic cylinder: In this case the operator can move the piston in both directions, and through a pump cause it to travel back and forth as required. This type of cylinder guarantees the highest level of operator control over the vehicle to be driven. To obtain the required movement, it will therefore not be necessary to wait for gravity to take effect and bring the piston back to the initial phase.

Single acting hydraulic cylinder: In this case the operator can operate the piston through a pump and hydraulic oil, but unlike in a double-acting hydraulic cylinder, the return phase is controlled by a spring that exerts the required pressure or simply by the force of gravity.

Plunger hydraulic cylinder: similar to the single-acting cylinder where there is no piston and hydraulic thrust is applied to the stem section.

Telescopic cylinder: it consists of tubular elements that slide one inside the other and multiply the travel length through several extensions.

PAGANI EUGENIO Experience

Thanks to 40-plus years of industry-specific experience, PAGANI EUGENIO aims to meet all possible needs in scenarios where, in order to ensure project success, thoroughness and know-how are essential right from the early stages of designing through to the end of production, and can offer special, non-standard cylinders based on customer drawings or drawings provided by our design department, based on customer specifications. These large cylinders, up to 11 metres in length and with diameters sized accordingly, can be supplied with virtually any type of finish and construction features, in compliance with all applicable safety parameters.

The cylinders that we offer reflect our product strategy, and since they are key elements for the operation of the machinery they are part of, and are subjected to enormous stress, they must obviously be highly resistant and able to ensure long-lasting efficient performance, in terms of power and precision, in all conditions and all environments.

Quality and efficiency are the result of the use of choice components made from only the best steel available on the market, meticulously assembled, and of the greatest care devoted to machining and accessory finishes in each individual case. Finally, quality and efficiency also stem from the rigorous supervision of each specific process phase.

Our production flow

- Initial project analysis;

- Development of CAD drawings for production;

- Possible FEM analysis of the components;

- Addition of specific technical data sheets to our ERP;

- Production planning with MES 4.0 information technology system;

- Programming of machine tools via CAM;

- Quality control of each single component according to our internal protocol;

- Cylinder assembling;

- Pressure test to ensure tight sealing, report according to EN10100;

- Painting according to specifications and suitable packaging.

Each implemented project comes with a technical file which includes:

- 3.1 EN10204 material certificate of the main components involved;

- Report of the measurements and tests carried out;

- Pressure test according to EN10100.

Cylinder packaging is also a major feature of the supply to ensure safe cylinder transport.

Our standard packaging is Europallet, with heat-sealed PVC straps and stretch film, while supports, decks and crates are made to measure.

Case history

September 13, 2022

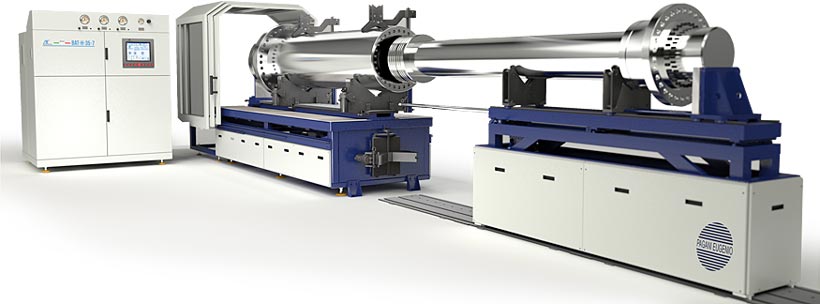

Our assembly and test bench for cylinders

In 2015, in cooperation with the company AF Automazione, we gave substance to a project for the installation in our facilities, of the first and most important test bench ever built, by such partner, up to that moment.