PAGANI EUGENIO srl is a one-stop supplier of machined, honed and chromed components for non-standard hydraulic cylinders produced to customer drawings. If a drawing is not available, our design department can also produce the necessary documents by examining an existing sample.

Our production

Our production of components mainly includes:

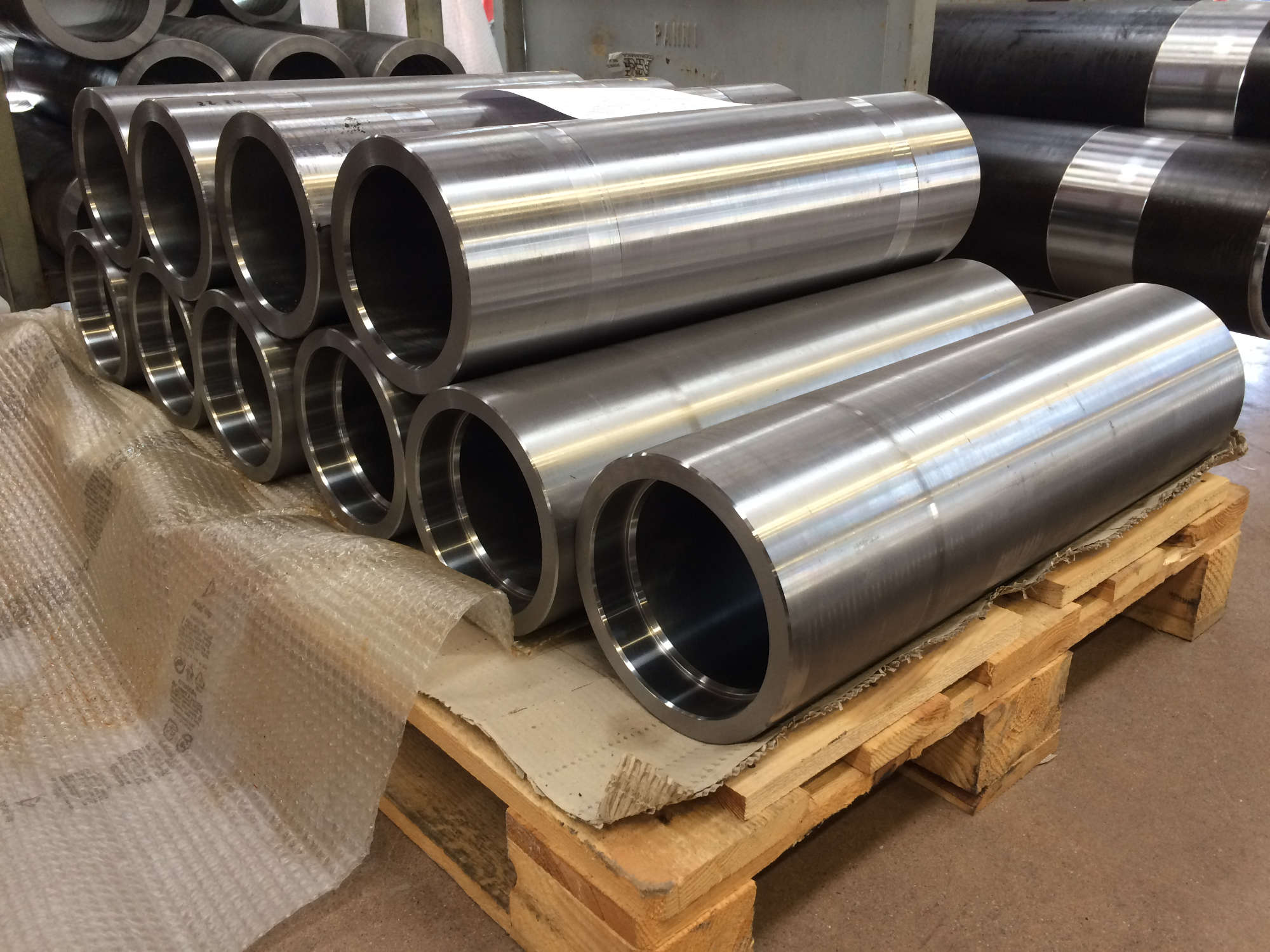

- Liners (welded and honed) for hydraulic cylinders;

- Tubes suitable for chrome plating or pre-chromed for concrete pumps;

- Honed stainless steel liners for feeders/dosing units;

- Compressor liners;

- Customised chromed rods for cylinders also with induction hardening treatment;

- Heads and pistons for special cylinders;

- Kits of customised gaskets;

- Deep bored rollers ready for balancing;

- Thick chromed and honed rollers.

Each component reflects the wealth of experience gained in more than 40 years of dedicated activity in the industry and is built strictly in accordance with well-tested internal schedules and procedures.

Production is analysed, planned and programmed according to organised flows and different sets of skills so as to leave nothing to chance, in accordance with ISO9001:2015.

Materials

The most widely used materials for our production are the following:

- Tubes for cylinders: E355+SR EN10305, E460+SR EN10305;

- Structural steels: E355AR EN10297, S355J2H EN10210, E590K2 EN10297;

- Tempering and alloyed steels: C45 EN10083, 42CrMo4+QT EN10083;

- Stainless steels: AISI304, AISI316, SAF2205, AISI630-17.4PH, AISI431.

These consistently top quality materials are always supplied with 3.1 EN10204 certifications. Please inquire with us about the feasibility of components to be made from alternative materials.

Our standard inspection policy guarantees functionality and product quality:

- Visual inspection;

- Measurement with traditional certified instruments;

- Roughness measurement;

- Chrome thickness measurement.

Another important plus concerns the packaging of each supply which must guarantee product integrity during transport.

Our standard procedure involves the use of protective coating, corrugated cardboard, bubble wrap or stretch film depending on the products to be shipped.

In highly critical cases, for example for externally chromed stems, the products need to packaged in custom-made fir wood crates.

In the case of intercontinental shipments, for protection against corrosion, it is possible to supply laminated packaging with a heat-sealed barrier material.

Case history

July 21, 2022

Survey and manufacturing of a random check chrome-plated rod

A relevant Italian company with branches in various eastern European countries, asked our intervention to revamp into optimal efficiency conditions a cylinder placed into an application for the waste management

June 21, 2022

Perfectly aligned honing

On behalf of one of our historical and most important client, we planned the definition of a production cycle combined with turning and honing which ensured the required geometries with reliable repeatability over the whole producon

June 21, 2022

Deep honing and drilling on design

For an application concerning the extactive and mining sector we built some hydrolic cylinders from one single S355 steel block. A kind of request pretty much difficult to comply with, which needs an accurate job.