Honing the inside of tubes and cylinder liners is a fundamentally important process which must primarily respond to the need to obtain a smooth surface, to ensure smooth sliding between two moving components, guaranteeing maximum efficiency and durability.

Standard vs tailor made

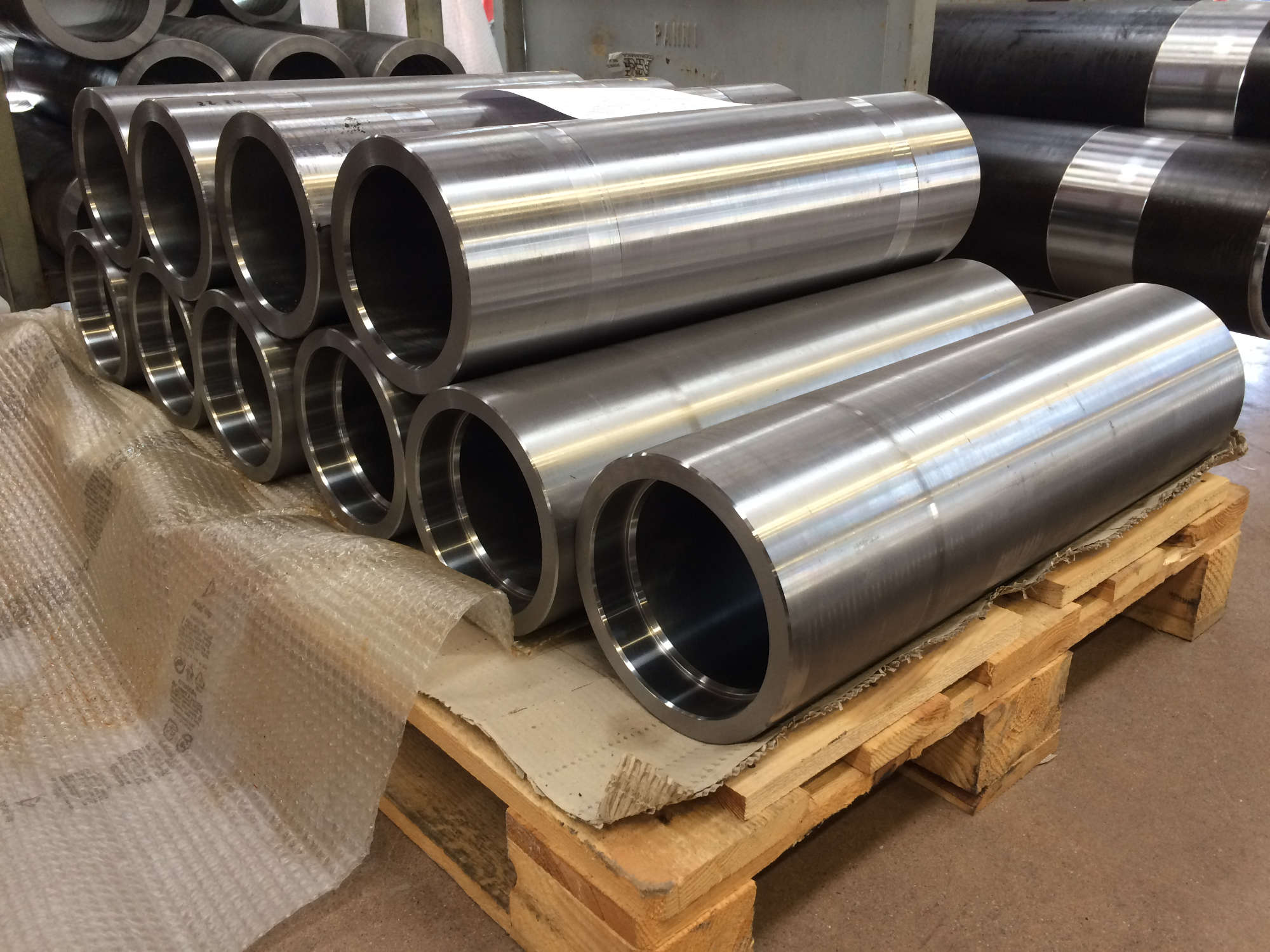

Internally honed tubes are available commercially as standard products, but it is not uncommon for certain limit conditions to occur which require non-standard products: special diameters, high thicknesses, steels other than standard.

A little more detail...

The honing process is carried out by means of a special tool, consisting of sectors in which stones or abrasive cloth are provided, and in rotary and linear motion, whose combined effect gives the surface its typical helical-looking shape.

The end result, when the procedure is carried out correctly, is a smooth surface, free of visual defects, with a roughness Ra lower than 0.20 my and Rt lower than 2.5my, such as to ensure an extended life of the gasket, and a tolerance H8 or H7 which guarantees an adequate sliding clearance of the piston guide shoes.

Attention to detail

One of the typical features of our machining process is our focus on every detail of customer projects – to achieve the best possible honing result. As proud specialists, we are able to start from mechanical piping to perform, in addition to other processes, honing to such a high precision degree that the best surface concentricity and perpendicularity can be guaranteed to even exceed cylinder pressure test requirements.

Case history

June 21, 2022

Perfectly aligned honing

On behalf of one of our historical and most important client, we planned the definition of a production cycle combined with turning and honing which ensured the required geometries with reliable repeatability over the whole producon

June 21, 2022

Deep honing and drilling on design

For an application concerning the extactive and mining sector we built some hydrolic cylinders from one single S355 steel block. A kind of request pretty much difficult to comply with, which needs an accurate job.

February 21, 2022

Non standard tube supply

We have made some honed tubes in Inox AISI 316, for one of our customers active in the field of Oil & Gas valves actuators, that stands with a great strategic importance for the energy sector.