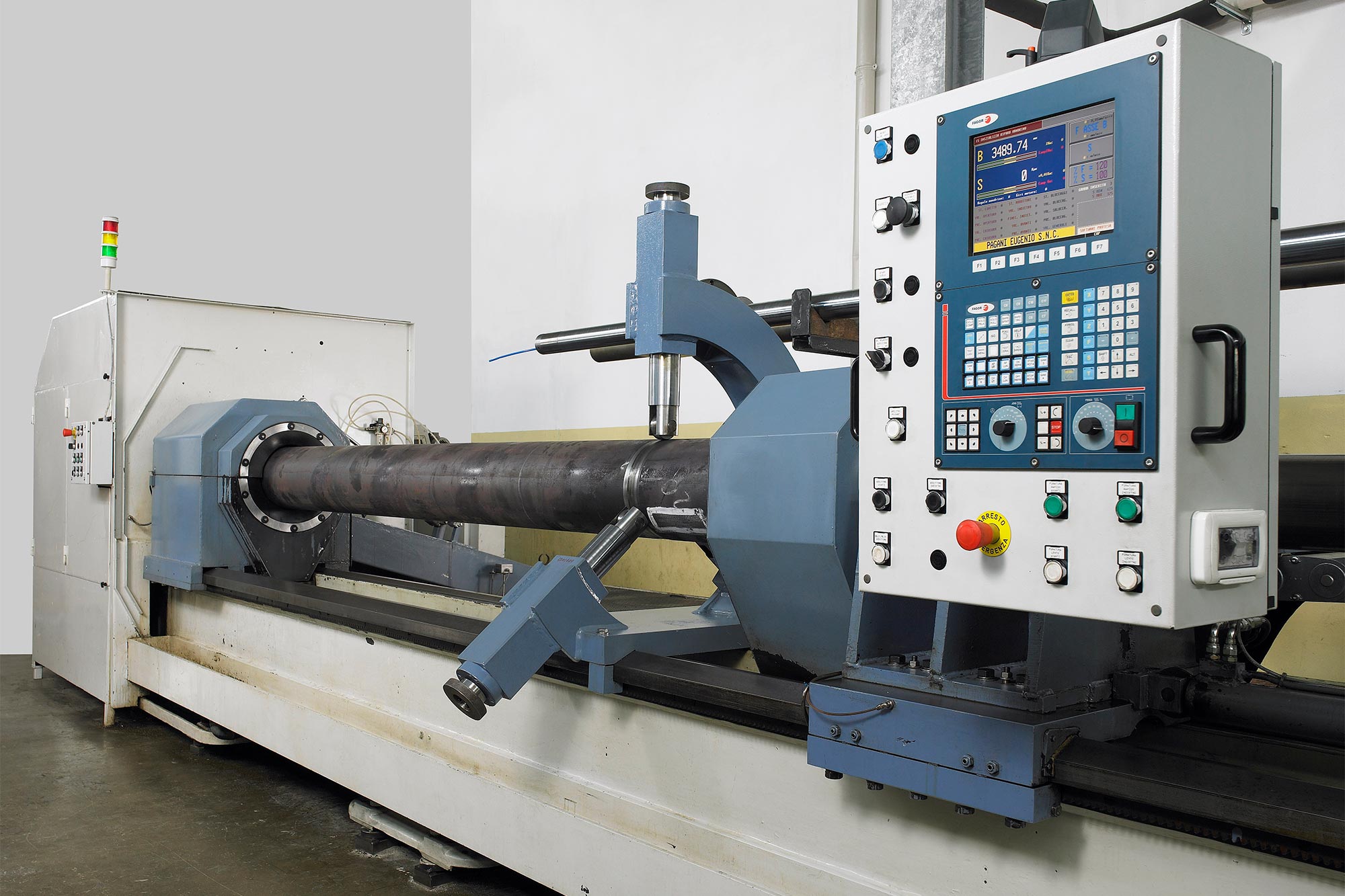

Deep hole boring, as well as deep drilling, is performed on hot rolled tube of considerable length and with a diameter many times larger than the standard; it is also often referred to as tube reaming. These tube are then often used as liners for hydraulic cylinders.

It is an internal roughing operation for hot rolled tubes produced according to EN10297, where the stock material to be removed varies according to the initial thickness of the pipe and determines the duration of machining operations.

Tube deep boring can be performed as a push or pull operation; the former option follows the original geometry of the tube while the latter bores a hole with better straightness characteristics.

Our production process

Our production process includes a first preparatory phase which consists in aligning the workpiece on the lathe; this phase is very important because it determines the quality of final machining which must be as concentric as possible with respect to the outside.

The importance of this operation should not be underestimated because hot rolled tubes, manufactured according to EN10297, have wide dimensional tolerance specifications for the outside diameter and thickness and for this reason, the desired bored diameter cannot be always obtained.

In this phase the unmachined tube sag is measured and if it exceeds a certain value, additional straightening on the hydraulic press is carried out.

The next steps of deep boring

Once this first phase is complete, the tube is ready to be deep bored or turned internally throughout its length, with special fixed measuring tools similar to drilling bits for deep drilling, called “wideners”.

The stock allowance removed in each pass generally ranges from 6 to 15 mm depending on the size of the insert that can be used.

After tube deep boring completion, we will have obtained a hole machined throughout the entire length, with roughness Ra between 6.3 and 12.5, with a stock allowance which can then be sanded down to a tolerance H7 or H8.

Inspections

The inspections carried out after machining completion are: visual inspection to detect any defects inside the tube, such as holes due to lack of material and instrumental testing using a micrometer, to both check the inside diameter dimension and measure the thickness of the tube at both ends, so as to determine the eccentricity tolerance between the inside and outside of the tube.

Additionally, our production process allows a workpiece to be obtained ready to be subsequently tailstock machined with external turning, guaranteeing a high degree of concentricity between the inside and outside diameter of the tube.